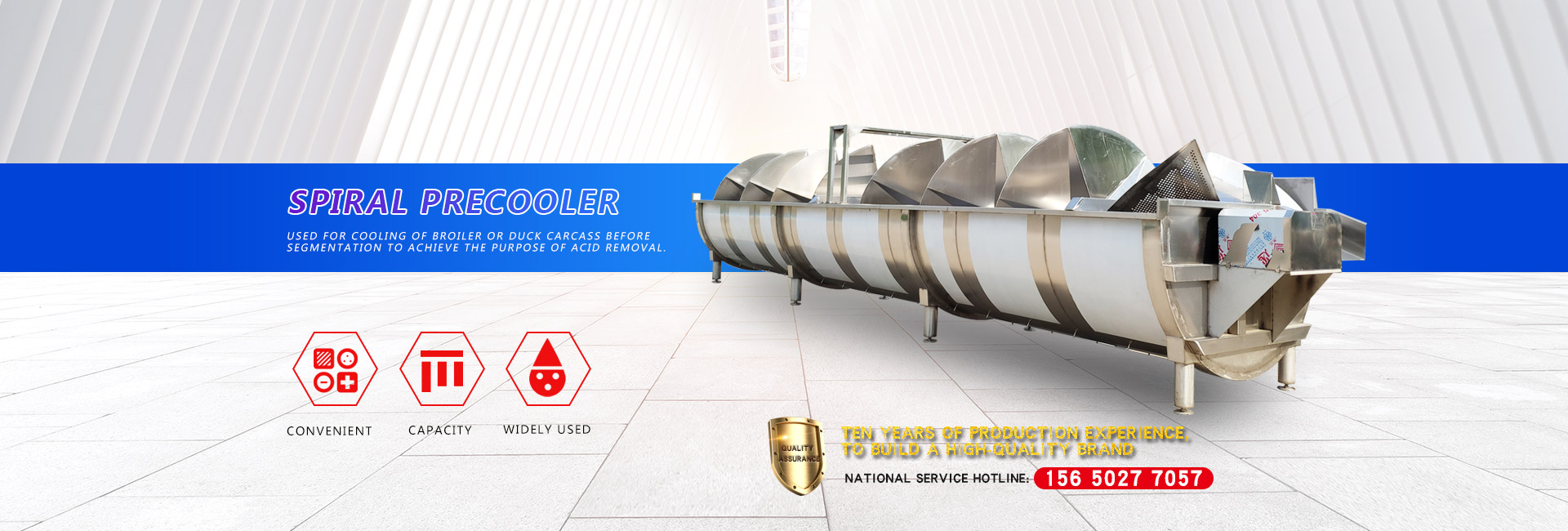

Reasonable equipment selection plays an important role in the successful construction of poultry slaughtering and processing projects, and can provide a basis for the calculation of power, power distribution, water and gas consumption. Therefore, on the basis of extensive investigation and study and drawing lessons from domestic and foreign technologies and experiences, according to the production process requirements and market supply, according to the principles of technological progress, economic rationality and production applicability, as well as the requirements of feasibility, maintainability, operability and energy supply, the investigation, analysis and comparison are carried out to determine the optimization scheme of the equipment. The main basis, basic principles and main contents of the following equipment selection are the back analysis of the complete equipment selection of poultry slaughtering and processing production line.

(One) Main basis for selection of complete equipment for poultry slaughtering and processing production line

1. In line with the requirements of relevant national industrial policies and standards, first select and adopt the appropriate scale slaughtering and segmentation processing equipment with high scientific and technological content, good economic benefits, low resource consumption, safety and health, and less environmental pollution of Chaoyang machinery. It is prohibited to select and adopt the equipment restricted and eliminated by the current national order. Secondly, standard equipment and finalized products shall be selected and adopted as far as possible. The design, manufacturing, installation, inspection and other technical conditions of the equipment can be constrained by the existing basic standards, mode standards and food safety standards.

2. Safety and health standards, equipment matching and safety and environmental protection to ensure safe production. According to the principle of ergonomics, considering the impact of the equipment on the environment and operators, the production stability is high and shall not cause danger to operators. Ensure that the supporting equipment is complete, the production operation is simple, and the cleaning and maintenance are convenient, so as to ensure that the final product meets the requirements of food safety and hygiene.

3. To meet the requirements of the process technology scheme, the adaptability and matching of the production scale of the project, the rationality of the matching between the main equipment and auxiliary equipment, meeting the process technology requirements and ensuring the processing output and quality are mainly considered.

(Two) Basic principles for selection of complete equipment for poultry slaughtering and processing production line

1. The principle of matching with the production capacity: the processing capacity, specification, model and power consumption of the equipment must match with the corresponding output. Fully consider the reasonable configuration of processing equipment for each process to ensure that the production capacity of each equipment is balanced.

2. The principle of equipment progressiveness and economy: when selecting equipment, while meeting the process and technical requirements, and considering the reasonable technical and economic indicators, it not only meets the requirements of production, process and meat hygiene, but also has high performance cost ratio, perfect functions, low operation and maintenance costs, low energy consumption, high processing capacity and long service life, so as to obtain better economic benefits.

3. The principle of applicability and reliability shall adapt to the changes of local natural, economic and social conditions. The same production line shall realize multi process slaughtering and processing as much as possible and be able to adjust production. It has broad prospects for development and is conducive to expanding production at home and abroad.

(Three) Main contents of complete equipment selection for poultry slaughtering and processing production line

1. In the process of equipment selection, first of all, carry out market research at home and abroad, collect data on relevant livestock and poultry slaughtering and processing equipment, and package the product name, regular model, production capacity, supporting power and price according to the equipment to be selected according to the production scale.

2. The technical requirements for equipment type selection mainly include that the equipment type selection and matching can meet the process technical requirements and processing quality, the service life, reliability, operability and health safety requirements of the equipment, the technical conditions for equipment installation and commissioning and the technical service requirements for maintenance. New technologies and equipment shall be identified to meet the general technical requirements for food equipment, cleaning The disinfection lamp device shall meet the production process requirements.