The maintenance of poultry slaughtering equipment is very important for the production of slaughtering line. Poultry slaughtering line will have some normal wear and tear in the production process. Therefore, maintenance is particularly critical. Here are the parts maintenance methods of the slaughtering line:

1. maintenance method of head motor:

The slaughtering line must not water the motor, because this may cause damage to the motor and affect the use. It will also shorten the service life of slaughtering equipment.

2. Chain maintenance method:

The chain of the slaughtering line may cause the original lubricating oil to heat up and volatilize after long-term operation, which may easily lead to imbalance, noise and crawling of the chain of the slaughtering line during operation. Add butter or thicker lubricating oil to the chain.

3. Repair and maintenance methods for head reducer of slaughtering line:

After three months of use, drain the engine oil in the gearbox, clean the gearbox with diesel or gasoline, and add new lubricating oil to the middle of the observation window immediately after draining. In the future, it is OK to change the lubricating oil once a year. Too much lubricating oil may cause the reduction gearbox to heat, and the motor protection switch will trip due to excessive motor load. Too little lubricating oil may cause the reduction gearbox to heat up, increase the noise and the reduction gearbox to hang and be scrapped.

- Home

- About us

- News

-

Products

- Poultry depilator

- Dip bath

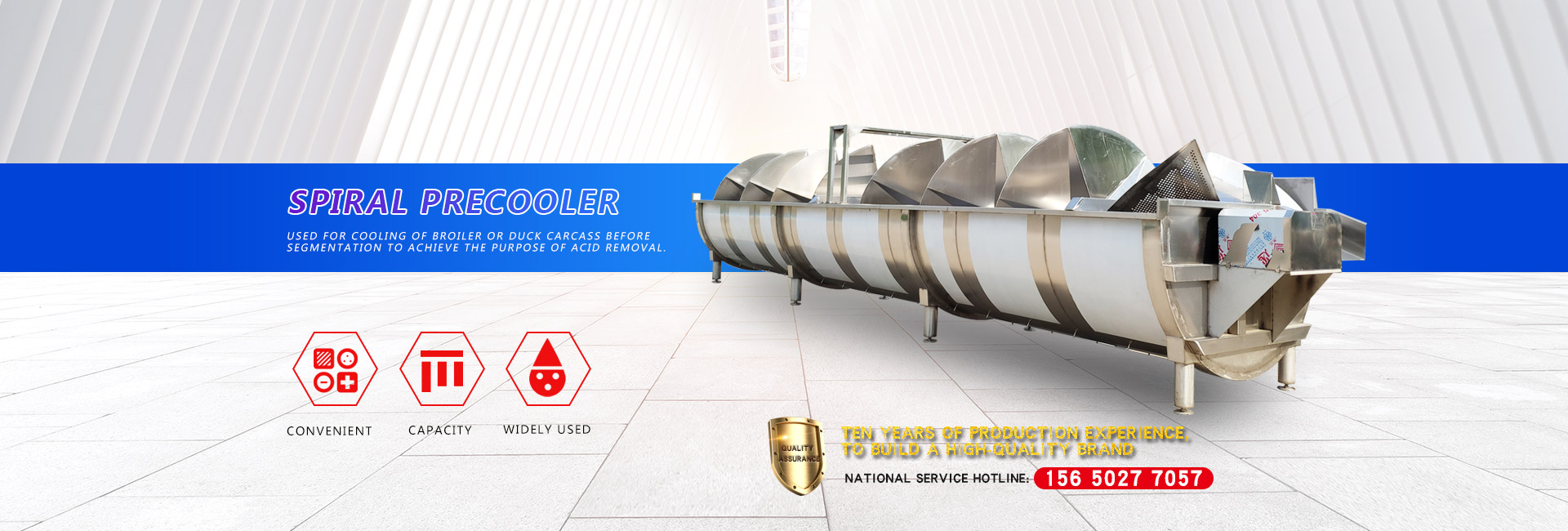

- Spiral cooling

- Strong spraying machin

- Frame washing machine

- Neck punching machine

- Dip wax tank

- Visceral guide chute

- Wax stripper

- Head pulling machine

- Duck (chicken) sausage

- Corona machine

- Oiling machine

- Automatic cutting mach

- Claw Machine

- Rabbit slaughter machi

- Gizzard peeling machin

- Automatic coupler

- Nine pieces of sliced

- Pipeline cleaning mach

- Poultry slaughtering e

- Conveyor belt

- Case

- Video

- Contact Us

Web site announcement

This website is the official website of Zhucheng Chaoyang Machinery Co., LTD. Please pay attention to slaughtering products and industry information

Contact us

Chaoyang machinery Co. LTD

phone:(Manager Zhu)15650277057

tel:0536-6480866

fax:0536-6480866

email:zczhaoyang@126.com

url:www.ahsytzjt.com.cn

Address: Shunwang Street Development Zone, Zhucheng city, Shandong Province

Company News

Company News

Precautions for maintenance of poultry slaughtering equipment

Source: Time:2022-06-08 15:55:47 views:

The maintenance of poultry slaughtering equipment is very important for the production of slaughtering line.

Copyright © all rights reserved◎Zhaoyang Machinery Co., Ltd.

Tel:0536-6480866 Fax:0536-6480866 Contact person: (Manager Zhu) 15650277057

Address: King Street Development Zone, Zhucheng City in Shandong Province Technical support: Hengtai interconnection

Website record number: Shandong ICP preparation of 14004351 -8