My friends from the countryside must have seen the lively scene of killing pigs and cattle. With the implementation of the fixed-point slaughtering system, the rate of point slaughtering in villages and towns is nearly 96%, and the phenomenon of private slaughtering and excessive slaughtering has been effectively curbed. Analysis of insiders: at present, there are more than 3000 mechanized slaughterhouses (farms) in China, 10 times more than before the implementation of the designated slaughtering system. The production equipment and technology of some designated slaughtering enterprises have reached or approached the world level. The slaughtering machinery and equipment assembly line is an inevitable development trend.

There are three main types of slaughtering and processing enterprises in China.It is understood that there are three main types of slaughtering and processing enterprises in China. First, enterprises above Designated Size (especially those with annual sales of more than 5million yuan) included in the statistical scope of the National Bureau of statistics are generally mechanized and modern slaughtering and processing plants; Some slaughtering and processing enterprises have begun to implement brand management, and there are more than 500 meat registered trademarks in China. An open circulation pattern with orderly management has basically taken shape. Progress has been made in breaking the regional market blockade. Some large slaughtering and processing enterprises have allocated production resources nationwide or in a wide range of regions. Relying on their own quality, brand and scale advantages, they have used circulation methods to expand the sales market. Brand meat chain stores, franchised stores and cold chain transportation have developed rapidly. Some high-quality pork products have been distributed across regions. Second, the designated livestock and poultry slaughtering enterprises approved by governments at or above the county level are mainly semi mechanized and manual slaughtering at present. Third, farmers slaughtered and ate by themselves and slaughtered and processed illegally. The quantity of such slaughtering and processing exceeded 40% of the total meat output.

Determine five key tasks of livestock and poultry slaughtering industry management in 2015 year.

At the beginning of February this year, the Ministry of Agriculture issued the notice on doing a good job in the management of the livestock and poultry slaughtering industry in 2015, which identified five key tasks for the management of the livestock and poultry slaughtering industry in 2015 year. Accelerate the legislative process of the regulations on the administration of livestock and poultry slaughtering, draft and issue a number of regulations, normative documents and technical standards for the administrative departments of livestock and poultry slaughtering, and study and formulate local regulations and government regulations such as the supervision and management measures for small pig slaughterhouses (sites) in towns and townships, and the management measures for cattle, sheep and poultry slaughtering. Steadily promote the transformation and upgrading of livestock and poultry slaughtering industry. Study and formulate the development plan of the national pig slaughtering industry, and timely formulate and revise the setting plan of local designated pig slaughtering enterprises. Integrate the statistical monitoring system for livestock and poultry slaughtering, optimize the statistical sample enterprises, establish a team of statistical informants, and do a good job in statistical monitoring of livestock and poultry slaughtering. We will strengthen research on the development of the livestock and poultry slaughtering industry, promote local research to introduce policies and measures to promote the development of the livestock and poultry slaughtering industry, and timely warn and predict the development of the livestock and poultry slaughtering industry and the quality and safety situation of meat products.

In addition, according to the requirements of the outline of the development plan for the national pig slaughtering industry, a number of large designated slaughterhouses with an annual slaughtering capacity of more than 1million pigs will be cultivated in the national pig production areas in 2015 to further improve the industry concentration. With the introduction of the policies of relevant national departments and the attention paid by provincial and municipal health departments to the designated slaughtering, some slaughterhouses with shallow qualifications and backward equipment will be gradually eliminated in the market competition, while large slaughtering enterprises prefer the complete slaughtering equipment production line, and the demand for slaughtering machinery is increasing. Therefore, the production line of slaughtering equipment has become the inevitable trend of the development of slaughtering industry.

Development of slaughtering machinery in China.

In terms of slaughtering equipment technology, reviewing the development of meat processing machinery and equipment in China over the past 60 years, it is the most important achievement to improve the localization rate and automation level of livestock and poultry slaughtering machinery and equipment.

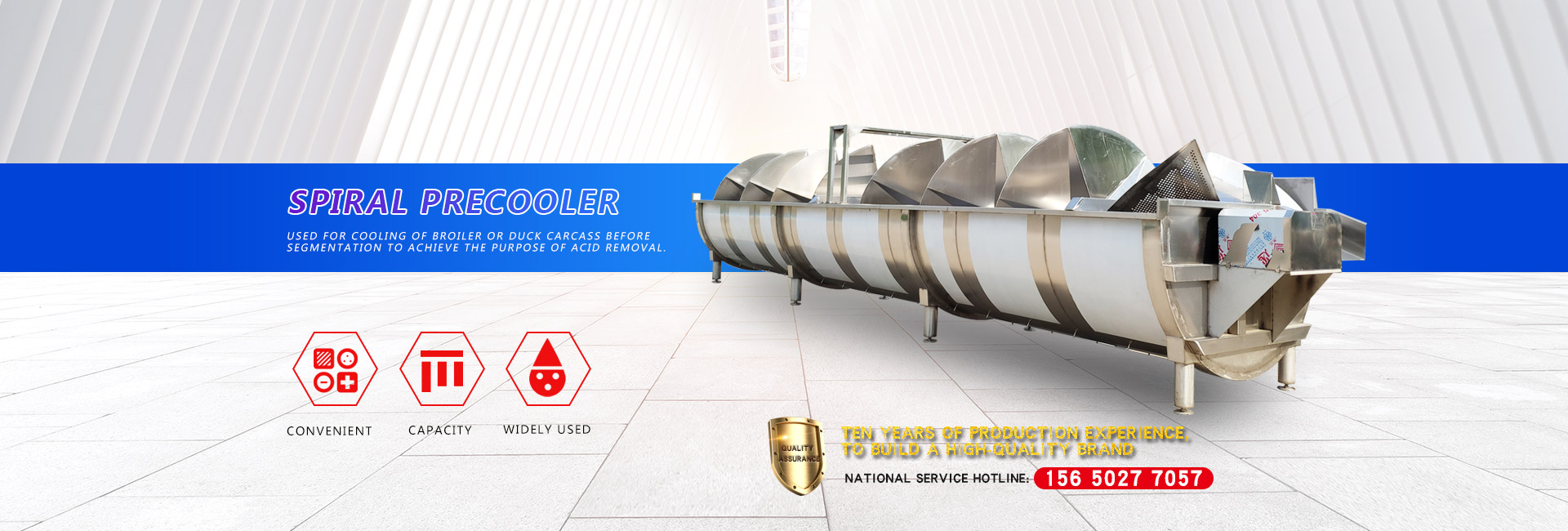

Various slaughtering machines include: pigs, cattle, sheep, poultry and other different categories according to the characteristics of raw materials; According to the process flow, it is divided into different parts, such as waiting for slaughter shower, traction and transportation, stunning, lifting and hanging, stabbing and bleeding, cleaning, scalding, roughing (depilation), shaving (depilation), singeing, shaving, polishing, peeling, synchronous inspection, splitting and cutting, by-product treatment, sterilization and pre cooling. In addition, there are also bone cutting machines such as conveyors, cutting saws, bone and meat separators, dividing machines and cutting meat packaging equipment.

With the strong support of governments at all levels for the research and development of equipment manufacturing industry in the livestock and poultry slaughtering and processing industry, a large number of domestic slaughtering and processing technologies and equipment have achieved technological progress, including vacuum blood collection devices, automatic temperature control (live pig) steam scalding tunnels, high-efficiency depilation technologies and equipment, crawler type u-beaters, automatic positioning splitting machines, electric stimulators, etc., which have improved the automation, modernization and localization rate of slaughtering production, To some extent, it has got rid of foreign technological monopoly and restriction.

In addition, some technical equipment, such as high-efficiency hair removal technology and equipment, have achieved major breakthroughs in the field of Chinese traditional meat product raw material treatment. In the late 1990s, a new round of expansion, new construction, technological transformation and equipment upgrading emerged in the meat processing machinery and equipment enterprises on the basis of restructuring. The industrial investment is more than 10 billion yuan every year, mainly focusing on the technological progress of slaughtering and processing.

In the early stage, it included the poultry slaughtering division line, followed by the slaughtering division line of pigs, cattle and sheep, but the imported equipment accounted for a large proportion. For example, pig slaughtering and processing has introduced three-point fainting, hollow bloodletting, steam scalding, flame burning and other production lines from Germany and the Netherlands; Poultry slaughtering and processing has introduced fully automated production lines for slaughtering, depilation, cooling, weighing and specification segmentation. The production capacity, production scale and technical equipment level of livestock and poultry slaughtering and processing are gradually approaching the world level.

At the same time of introducing foreign equipment, domestic machinery factories also began to digest, absorb and imitate imported equipment, and then develop their own. In 2004, more than 60 meat processing machinery factories in China were able to produce most of the Western-style meat processing equipment, basically meeting the production process and health requirements of general meat processing factories. In recent years, the gap between domestic meat processing machinery and the world level has been further narrowed. Complete sets of technologies and equipment such as meat cold processing have achieved a major leap. The export volume has continued to increase, with an increase of at least 25%. Some equipment has even entered the German market where meat machinery is very advanced.

China's slaughtering equipment industry, on the one hand, develops with the favorable guidance of national policies, on the other hand, it also needs to rely on advanced production equipment to win the market.