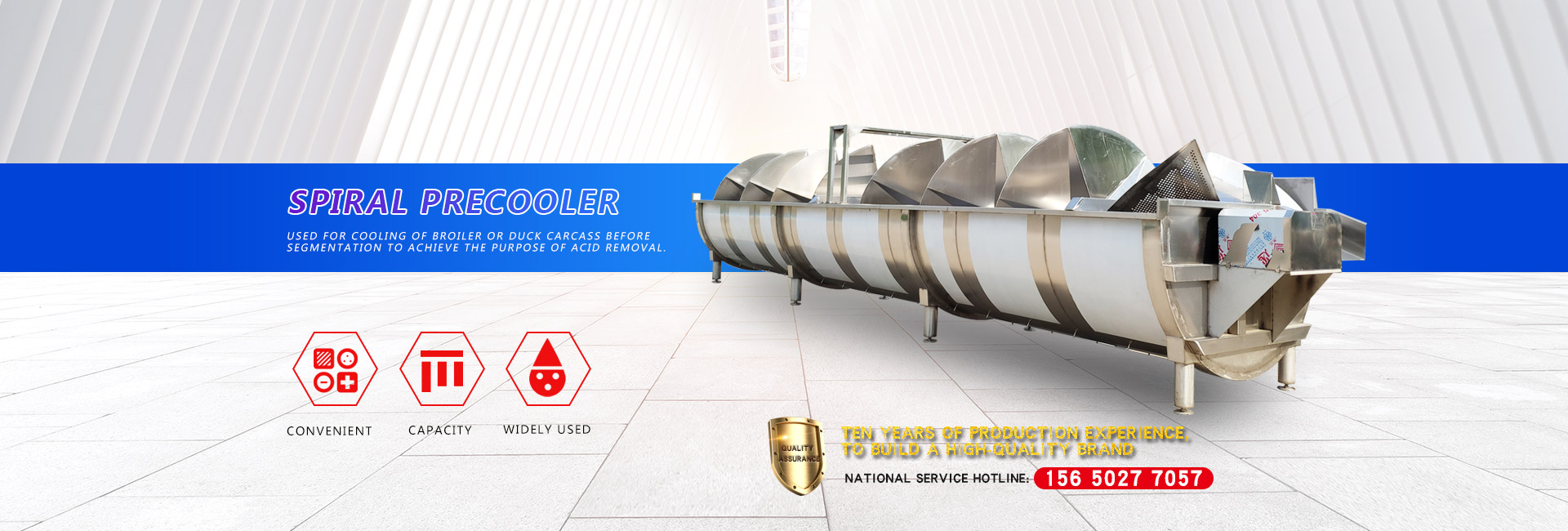

Broiler slaughter and processing technology research since 1980s, especially in 1990s, broiler breeding industry in China has been rapid development. Broiler breeding industry, the development of broiler processing industry is bound to promote the development of. My courtyard in the middle period of the eighties of the 20th century. The effects of the China imported Dutch Mayne and stoke, broiler slaughter and processing complete sets of equipment, grasp first-hand materials, according to the data analysis and comparison and Research on equipment performance working principle, structure and material characteristics, developed in line with the national conditions, with leading domestic and international advanced level of broiler slaughter and processing complete sets of equipment. From the big aspect, the process of chicken slaughter and processing is mainly divided into 4 areas, namely, the pre processing area, the middle area, the pre cooling area and the segmented packaging area. Its process is as follows: gross chicken hanging, sedation, (MA), slaughter, electric hemp, sugar, scalding, hair removal, eviscerated, pre cooling, packaging, segmentation.In our design and installation of broiler slaughter and processing equipment for more than 10 years, not only processing equipment has been continuously improved and improved, the process of broiler processing has also changed a lot. Chicken consumption users of broiler processing plant broiler quality also put forward higher requirements. In recent years, the processing plant in recent years, the process flow and important technical parameters of the 4 areas to be discussed.

1, the former processing areaThe treatment area refers to the area from the processing broiler chicken transport unloading to hit the net. The process is as follows: cage, hanging chicken, sedation, (MA), slaughter, blood, electric Ma, blood, scalding, hair removal, cutting claws (hanging). For small and medium sized chicken slaughtering plant can not be divided into cage. Chickens usually packaged in plastic basket, built 7 cage 1 stacks by truck to electric slaughtering plant, each basket of 8-10 chickens. Cage machine is the 7 cage 1 stacks of chicken into a cage cage feeding into the chicken hanging on the conveyor belt. Hanging chicken personnel from running in cages to chicken slaughter conveyor chains hang, the general should be according to per hour hanging 1200-1500 labor strength arrangement. Chicken is hanging to hook, should run 30-40s in the dark passage, the chickens to be calm to slaughter, in order to reduce the struggle. After slaughter 10s for electrical anesthesia, the strength of the electric hemp should be guaranteed by the current of each chicken body is 18-20mA, the electric anesthesia time is 8-10s, the voltage is usually between 35-60V. Use of alternating current or direct current. After the slaughter of killing time is 4.5-5.5min. Killing time is too short, blood ungodliness, affecting meat quality; time is too long, dehairing adverse and weightlessness, reduce meat rate. After killing the chicken body is transported into scalding machine. Scalding machine and dehairing machine with key equipment before the treatment area, scalding effect directly affects the quality of chicken. The requirement of the machine is mainly to ensure the time of soaking, the temperature of the soaking and the uniformity of the temperature of the soaking pool. The temperature difference of the water temperature in the soaking bath should be no more than 0.5 degrees C. The condition of turning water in the soaking pool has a great influence on the soaking effect. At present, there are 2 kinds of mixing methods, namely, water pumping and air blast. From the point of view of the various manufacturers of observation and investigation, the blower to superior to pump, pump usually drift chicken, chicken, drift chicken directly influence the hot chick dorsal permeability, and lead to dirty yellow skin and hairs removal. In order to removal of wampee and hairs, often have to improve scalding temperature. However, increasing the temperature will appear after breast blanching phenomenon, which is not allowed. The author in Tieling a company debugging scalding pool, appeared with breast not both the contradiction of wampee. Temperature in 58.1 OC wampee and hairs are meet the requirements, but the breasts generally blanching, water temperature in 57.6 DEG C, breast normal, but wampee and mouser stock is seriously, at this time the scalding time is 87s. After 2 days of debugging, the hanging chain of the water in the soaking pool is shortened, and the time of killing is unchanged, the immersion time is shortened to 82s. At this time the hot dip temperature to 58.1 DEG C, hair removal effect is good, there is no white breast hot phenomenon, affirmed by the user. Dehairing machine should be located close to the hot dipping machine, chicken body scalding shall commence immediately after molting machine, dehairing machine above should spray proper amount of hot water, to lubricate the skin refers to and chicken body, water temperature in the 35-40 degrees C is preferred. In order to make the net chicken body hairs and wampee, ensure adequate moulting time is particularly important, usually should ensure that more than 30s. For medium and large broiler slaughtering plants, should be equipped with coarse and fine picker picker. Defeatherer pulley speed also affect the quality of chicken,The speed is too fast, the skin refers to the chicken body impact increases, easy to damage the chicken body and wing broken, broken claw. Skin refers to the disc speed is too slow, but also not conducive to the moulting. After many years of practical exploration, the skin coarse dehairing machine refers to the rotation speed of the disc at about 950r/min is better, fine dehairing machine skin refers to the rotation speed of the disc in 750r / min is better. The hardness of the skin has a direct impact on the moulting effect, usually refers to the skin

Hardness of Shao Er A45-50. In order to remove the hair on the net head, usually a perm in first slot defeatherer or scalding machine, ironing head slot length to make a hot dip 3-5s is better, the temperature in 70 degrees C. After the hair removal, the chicken body is automatically cut off the claw of the claw, and the chicken body is in the middle of the drawing area. Some manufacturers in order to ensure the quality of chicken, using artificial claw cutting. 2, in the middle of the area

In the drawing area refers to the end of Mao has to be removed, chicken offal, head neck skin and clean the process area. The process is as follows: Hang, pick Xiaomao, pull head, open neck skin, cut neck skin, open resonator, dig offal, liver, divided into gizzard, pick tripe, cutting head, pull the craw, cutting