According to the size of domestic livestock and poultry, the hair removal machine has different technical requirements, so the market has derived chicken hair removal machine, sheep hair removal machine, pig hair removal machine, rabbit hair removal machine and other equipment. In addition, it can be divided into spiral type, roller type and cylinder type according to different structural composition. Compared with manual depilation, the application of mechanical equipment not only reduces the amount of manual labor and improves labor efficiency, but also has better depilation effect. Nowadays, slaughterhouses are more and more concentrated, and the demand for depilation equipment is also further increased. When handling the hair of small poultry such as chicken, duck, goose, pigeon and quail, the fine hair gives people a headache. According to the author's understanding, the previous cylindrical depilator can not handle fine wool. Therefore, there are vendors using asphalt and rosin (both industrial agents) for auxiliary treatment in the market.

Fine hair, harmful to consumers. Today's round hair removal is equipped with wolf tooth type hair removal stick on the original basis, which better solves the problem of being unable to handle fine hair. Some enterprises have also developed five axis, seven axis and other poultry hair removal machines, which use the rolling of five or seven hair beating axes to remove the hair of poultry. The distance between the depilation axes of the depilator is adjustable, which can reduce the damage rate of poultry to a certain extent and improve the depilation effect.

Generally speaking, the hair of small poultry is of commercial value, so it is more advantageous for slaughtering enterprises to have the same hair outlet of small poultry depilation equipment. In addition, some small poultry depilation equipment specially notes that they cannot be cleaned directly with water spray pipe, but need to be cleaned and dried with sponge, soft cloth, etc., which increases the workload of operators to a certain extent. The cleaning mode and drying procedure of the equipment can be considered.

With the further development of society, the slaughtering industry will continue to develop towards mechanization, centralization and environmental protection. As an important member of slaughtering equipment, depilation equipment should also move closer to these directions. For example, the hair after depilation can be collected and reused with a built-in filter system. In addition, at present, the depilation equipment of many enterprises has been fully automated, which further reduces the pressure of talent shortage in the slaughtering industry and makes depilation easier.

Of course, the depilation of poultry is actually affected by many factors. For example, the temperature in the previous soaking and scalding process has a significant impact on the depilation process. If the temperature is too hot, the depilation equipment is easy to remove the skin and meat together, and insufficient temperature will make it difficult to remove the hair. Therefore, the author believes that these problems should also be taken into account in the further research and development of depilation equipment, so as to produce equipment more in line with market requirements.

- Home

- About us

- News

-

Products

- Poultry depilator

- Dip bath

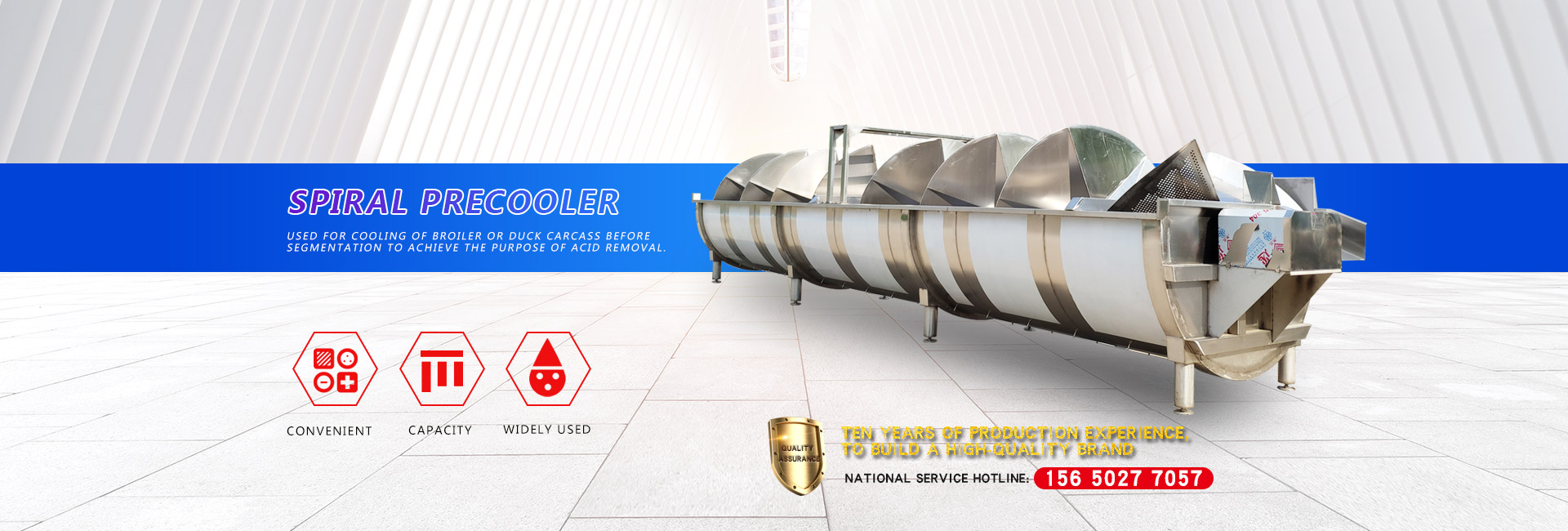

- Spiral cooling

- Strong spraying machin

- Frame washing machine

- Neck punching machine

- Dip wax tank

- Visceral guide chute

- Wax stripper

- Head pulling machine

- Duck (chicken) sausage

- Corona machine

- Oiling machine

- Automatic cutting mach

- Claw Machine

- Rabbit slaughter machi

- Gizzard peeling machin

- Automatic coupler

- Nine pieces of sliced

- Pipeline cleaning mach

- Poultry slaughtering e

- Conveyor belt

- Case

- Video

- Contact Us

Web site announcement

This website is the official website of Zhucheng Chaoyang Machinery Co., LTD. Please pay attention to slaughtering products and industry information

Contact us

Chaoyang machinery Co. LTD

phone:(Manager Zhu)15650277057

tel:0536-6480866

fax:0536-6480866

email:zczhaoyang@126.com

url:www.ahsytzjt.com.cn

Address: Shunwang Street Development Zone, Zhucheng city, Shandong Province

Trade news

Trade news

Depilation equipment makes poultry slaughtering easier

Source: Time:2022-06-08 14:56:14 views:

According to the size of domestic livestock and poultry, the hair removal machine has different technical requirements, so the market has derived chicken hair removal machine, sheep hair removal machine, pig hair removal machine, rabbit hair removal machine and other equipment.

Copyright © all rights reserved◎Zhaoyang Machinery Co., Ltd.

Tel:0536-6480866 Fax:0536-6480866 Contact person: (Manager Zhu) 15650277057

Address: King Street Development Zone, Zhucheng City in Shandong Province Technical support: Hengtai interconnection

Website record number: Shandong ICP preparation of 14004351 -8